Chris - Illinois

Automated precision • 500,000 bushels annually

Chris

Automated precision

The automated adjustments have eliminated the guesswork. We can focus on other operations while the dryer runs efficiently.

In-Depth Interview

Q: Why did you buy a Dryer Master in the first place?

A: We bought the DM510 to automate and remotely control our Grain Handler 2416.

Q: How much training was required to operate the Dryer Master?

A: The system is very intuitive. After a few hours of initial setup and training with our dealer, we were able to operate it confidently.

Q: How often do you typically calibrate your outlet moisture sensor? And what is your calibration procedure?

A: During harvest we sample and calibrate every 1 to 1.5 hours. We press the sample button, run it through our Perten tester three times, average the results, and enter the moisture into the DM510.

Q: How does the Dryer Master change the way you dry?

A: The automated adjustments have eliminated the guesswork from our drying operation. We can focus on other harvest activities while maintaining consistent grain quality.

Q: Do you use DM-Mobile? If so how do you use it?

A: Yes, I monitor the dryer via an iPad while in the combine during the day and use my iPhone at home after work. It is used all the time the dryer is running.

Q: Have you contacted the Dryer Master Support Centre? What was your experience?

A: Their support team has been excellent. They're always available when we need assistance and provide clear, helpful guidance.

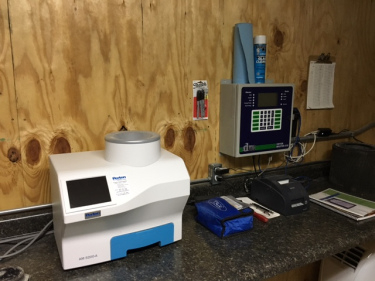

Installation Gallery

View Chris\'s actual dryer installation and Dryer Master control system setup

Quick Facts

Equipment Setup

DM Mobile User

This customer uses DM Mobile for remote monitoring and control of their grain drying operations.

Experienced User

10 years of experience with Dryer Master systems.